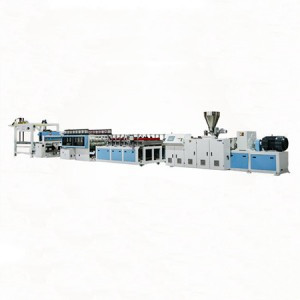

PLA Sheet and Forming Machine

ⅠMain Parameter

SJΦ63*2/Φ130 PLA Foam Sheet and Forming Machine

Ⅱ Machine List of the Line

Ⅲ Specific technoloy parameter

- 1.Mixing machine & drying machine

2.Feeding machine & Hopper

- 3.First -level double screw extruder

3.1 Power device

3.2 Extrude screw

3.3 Extrude barrel

3.4 Heating and cooling way

Adopt cast aluminium and high precision thermistor temperature

Extrude barrel cooling by water , using independent water circulation system

3.5 Screen changer device

Model of 150 , slide type , double holes , hydraulic driver , gear pump , motor power 3kw

- 4.Union pipe

- 5.Second-level single screw extruder

5.1 Motor device

5.2 Heating cooling way

Heating : Adopt cast aluminum heater , motor power 6kw / group

Nine group temperature control , RKC automatic temperature control system

Cooling : water cooling , install solenoid valve on the cooling pipe , with cooling water tank

- 6.Die head

- 7.Cooling and cutting device

7.1 Machine fram is welded by structural steel and steel plate .

7.2 Moded cylinder is welded by steel pipe , diameter is determined by sheet width .

7.3 Cooling fan is welded by steel plate , diameter is determined by sheet width .

7.4 Power of central blower high pressure machine 1500 W

7.5 Open mode : 10P cooling machine 1 set , cooling fan 1 set

8.Haul-off machine

8.1 Hall-off roll - 2 pieces diameter: Φ420mm , width 1300mm ;

8.2 Pressure roller -1 piece diameter: Φ130mm , width 1300mm ;

8.3 Pressing cylinder 1 set

8.4 Steel guide roll 2-pieces , diameter Φ74mm , width 1300mm

8.5 Motor power 3kw

8.6 Velocity 0-30m / min

8.7 With static electricity canceller

- 9.Winding machine

9.1 Machine fram is welded by structural steel and steel plate

9.2 Winding roll 2 set , circular arc panel , can stretch out and draw back , winding roll diameter 270mm , valid width 1300mm

9.3 Guider 1 set , diameter 175mm , valid width 1300mm

9.4 Telescopic cylinder 1 set

9.5 Torque motor 2 set , torque 16N , torque contral

9.6 With static electricity canceller

- 10.Foaming agent injection pump

10.1 Substrate is casted by Q200 , natural ageing treatment

10.2 Ceramics plunger pump , route of plunger pump can be adjusted

10.3 Explosion -proof electric machine

10.4 With metering control system , 0-20L /h (infinitely variable control system ), nominal pressure 25Mpa

10.5 Structural style : worm speed reducer , N shaft driving

- 11.Electricity control cabinet and electricity parts

11.1 electricity control cabinet is made by steel with cooling fan

11.2 Inverter ( famous brand )

11.3 Breaker , relay (LG)

11.4 Temperature control sysyem ( RKC )

11.5 Other electricity parts ( famous brand )

- 12.Cooling Frame

Valid width 15m , length 5m .

- 13.Finished products